Converting Waste Tires Into

Valuable Green Commodities

About Us And Advanced Tire Pyrolysis

Problem

Each year in the United States alone, over 300 million automobile and truck tires are removed from service and scrapped. According to the United States Environmental Protection Agency, the need to manage scrap tires has given rise to numerous scrap tire management programs and brought about new laws and regulations in 50 of 50 states. The abundance of waste tires has created serious environmental concerns. Scrap tires historically have been discarded in various legal and illegal manners.

Today, waste tires continue to pose environmental hazards due to their chemical toxicity, non-biodegradability, flammability and water and soil contamination. Waste tires are breeding grounds for mosquitoes and vermin that spread diseases like west nile virus, and take up tremendous landfill space. Millions of waste tires are being buried or burned, which also poses serious environmental risks. Land acreage to accommodate waste tires is rapidly diminishing. Globally, the staggering number of waste tires is in the billions.

Solution

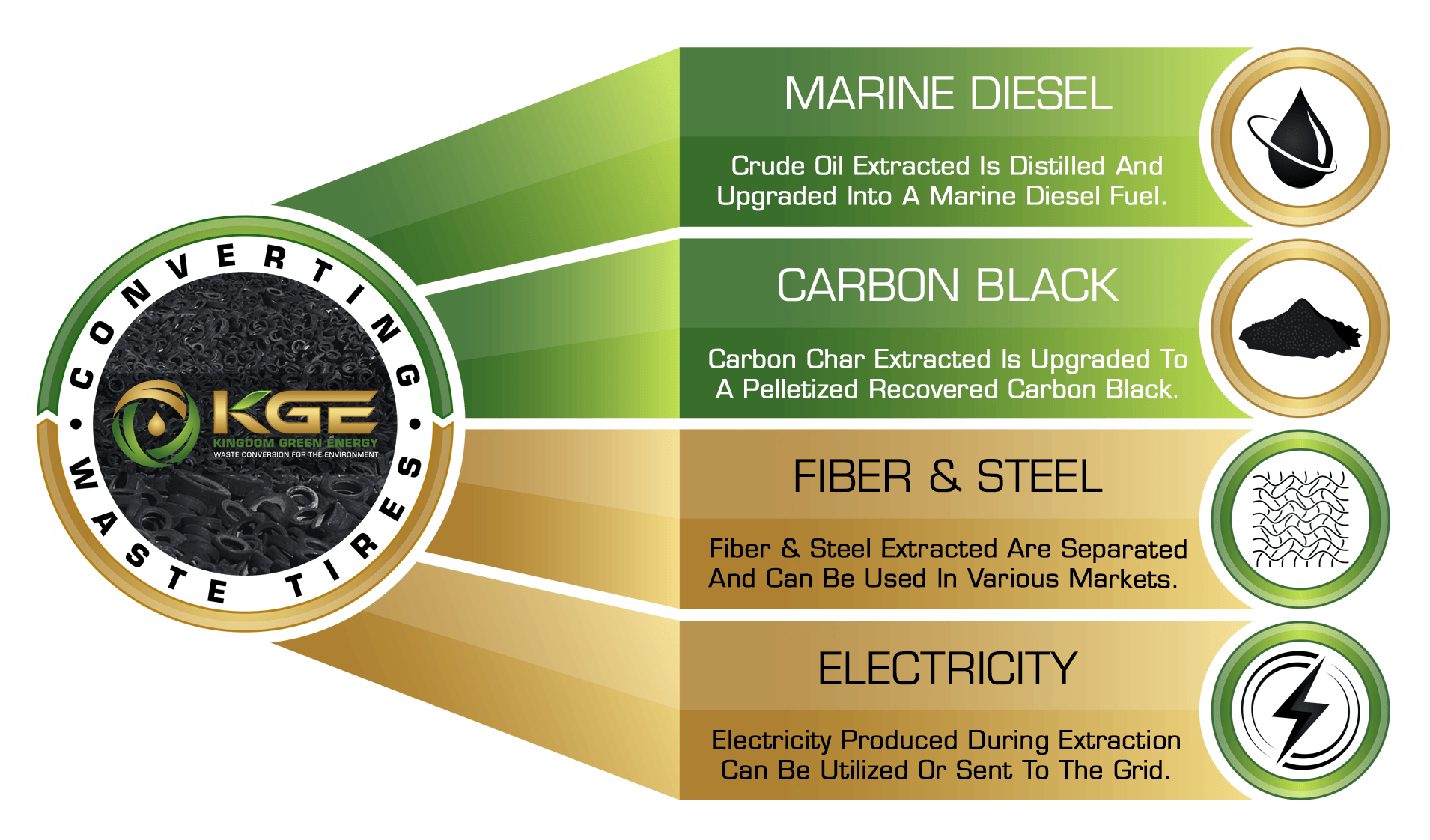

Kingdom Green Energy will utilize a proven tire pyrolysis conversion technology that can deliver a significant environmental solution by converting millions of end-of-life waste tires into valuable liquid fuels, recovered carbon black, fiber and steel commodities. Electricity is generated during the process. This unique pyrolytic conversion process can help solve the global excess of waste tires, as well as environmental and regulatory objectives. Through this proven process, this technology converts 100% of the feedstock into commodities. The technology is scalable, modular and sizable to create any throughput-output desired.

After many years of extensive testing and research and development, KGE will utilize proven technology, using a highly unique thermal process that clearly demonstrates excellence and reliable output. Every aspect of the systems and sub-systems have been throughly tested and proven. This technology has been fully vetted by multiple internationally recognized professional engineering firms, including top chemical engineers. The liquid fuels, recovered carbon black and synthetic gas have all been rigorously tested by the top nationally recognized emissions and analytical chemical testing laboratories, which yielded excellent results.

Our Process

Tires consist of about 51% crude oil, 37% carbon and 12% other materials. The consistent BTU energy in waste tire material is about 18,700 BTU. This energy can be extracted.

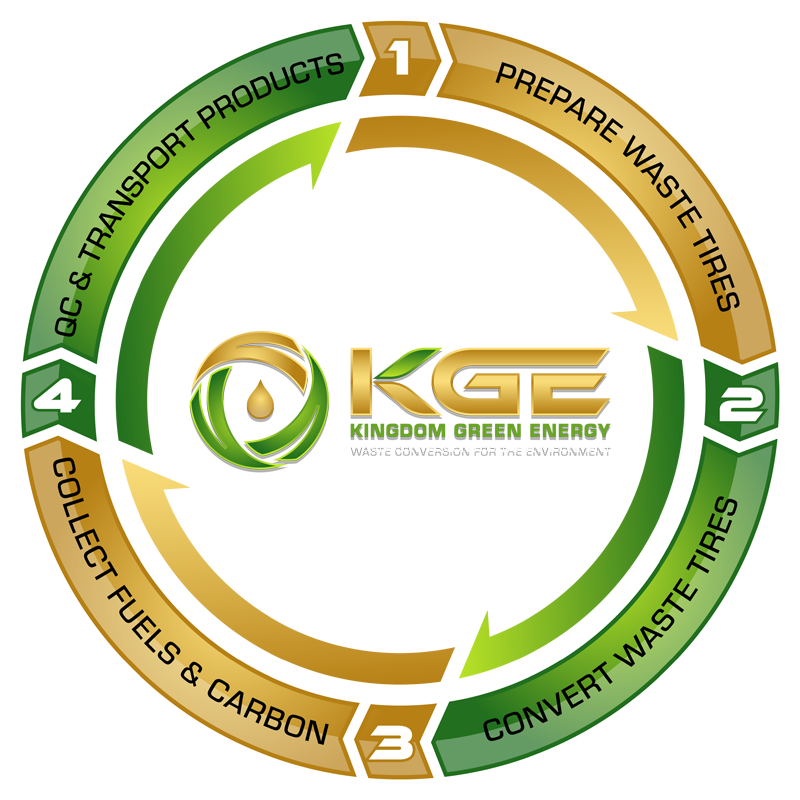

(1) Waste tire materials are prepared and chopped to size, while removing fiber and steel. (2) Tire materials then undergo a highly advanced thermal tire pyrolysis conversion process in order to convert the solids to synthetic gas. (3) The gases are cooled and the liquid fuels and recovered carbon black are separated and collected. (4) All products are upgraded and prepared for transport. This unique process creates a circular economy model that is profitable without subsidy.

Positive Impact

KGE tire pyrolysis contributes to four critical areas: